Robotic Kitchen Automation Levels

How does a level 5 automated kitchen look like?

I’m sure you are somewhat familiar with the self-driving cars levels of automation, perhaps following Tesla’s claims of offering “full self-driving” capabilities, later downgraded to level 2 (out of 5) of autonomy. These automation standards, published in 2014 by automotive standardization body SAE International as “Taxonomy and Definitions for Terms Related to On-Road Motor Vehicle Automated Driving Systems”, are useful to quickly address what we mean by self-driving capabilities. But cars are not the only thing that is getting automated, kitchens are being automated too!

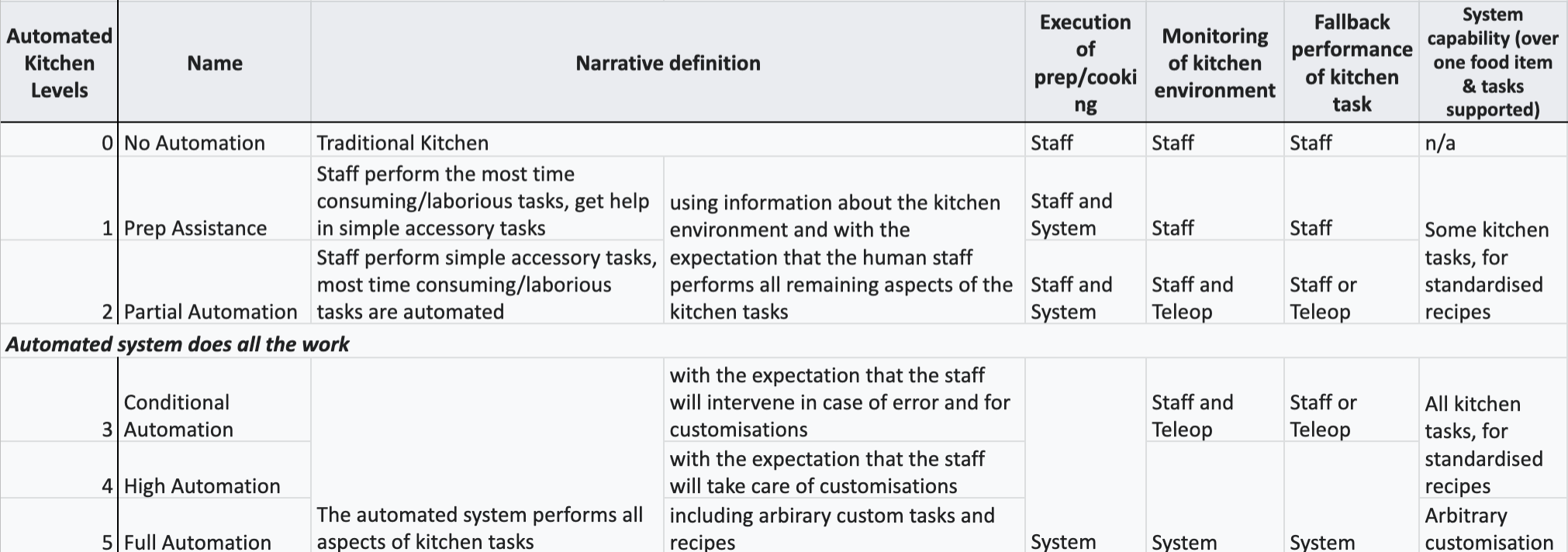

As there is no current standardisation on what “automated kitchen” or “robotic kitchen” means, I will take a shot at drafting how kitchen automation levels could be defined. Having clear levels will help aligning expectations and seeing behind the hype. I will draw from my experience at Nyrvan and take strong inspiration from the self-driving automation levels, as they adapt well to be repurposed for kitchens. The main conceptual difference is that while self-driving automation levels have safety implications, kitchen automation levels are mainly impactful on the level of savings and flexibility that a kitchen owner can expect.

Don’t worry, it’s not going to be a 200-pages standard, indeed for now it’s going to be just a single table! I will mainly focus on commercial kitchens, but the same levels can apply to home kitchens. Without further ado, here you have it:

Let me comment on the levels:

-

Level 0: A simple low tech traditional kitchen, everything is done manually apart from the use of standard appliances such as refrigerators and ovens.

-

Level 1: Smart appliances reduce the kitchen staff burden by automating simple tasks. For instance, smart ovens and fryers remove the need to be vigilant in the cooking process and to monitor the oil temperature. Many fast food chains and QSRs (Quick Service Restaurants) can already boast to have reached this level in production.

-

Level 2: There is a large jump in capabilities between level 1 and 2, since tasks which are very time consuming in a traditional kitchen are automated. For instance assembling bowls, putting toppings on pizzas or stirring rice in a wok are all tasks which require active attention from the staff. There are few systems with these capabilities in production, but we should expect this to change soon as the cost of robotics keeps falling and computer vision is getting more robust. If something goes wrong, the staff is supposed to intervene and restore the autonomous flow. In some cases a teleoperator can intervene and fix the situation remotely.

-

Level 3: The automated system handles the whole recipe from start to finish. For instance starting from dough and ending into a piping hot sliced pizza or preparing sushi starting from raw uncut fish. Supervision of staff is still mandatory to handle mistakes and failure in the process. Recipes are standardised and hard customisations are left to the kitchen staff. As an example, a pizza-robot may support the 50 most popular toppings and a standard baking process, but not the key extra ingredients or preparation steps which make your local pizzeria special. As with level 2, we will see sustained adoption of these systems in the 2020s.

-

Level 4: The main difference with level 3 is that the system is very robust and deviations from quality standards are rare. This is a small step in terms of capabilities, but a big engineering challenge. Kitchen staff is present in the cooking process only if customisation is needed, but not for routine quality control. For QSRs with standardised and fixed menus this equates to full autonomy. As handling all the edge cases is a very hard problem, we will likely wait until the 2030s to see large chains adopting this level of automation. At this stage we will literally have vending machines which are on par with the quality level standards of today’s QSRs.

-

Level 5: Arbitrary customisations and recipes are available, any step of the cooking process is controlled in fine detail. Do you want a large pie with bacon-pineapple and cheesy crust? Done! This level contains a vast quality range, going from simple takeaway recipes to Michelin-star ones. The refinement of these systems will take many decades, but it’s clear that the impact on how we live will be dramatic. Coupled with an increase in food delivery efficiency, kitchenless flats could become the norm in densely populated areas. As automated systems can be managed remotely, recipes will be A/B tested at software pace by AI algorithms. There will also be trends toward hyper-personalisation of recipes, driven by previous orders feedback and personal data.

The division in levels is specific to a given food item. For instance reaching level 5 for pizza may be as hard as level 3 on ramen soups, so it should be fair to only compare automated systems inside the same food category.

So, is cooking getting fully automated? I don’t believe so, in fact I believe we will see an even bigger emphasis on cooking as a social and cultural activity. What is getting automated are repetitive kitchen tasks.

In closing, I want to again summon the comparison with self-driving and remark that while the self-driving industry is expected to be a multi trillion dollar industry, not much has been discussed about the autonomous kitchen space. And while it’s unclear if personal vehicles will be a big thing in the future given trends towards remote work, walkable cities and car sharing, we are definitely going to keep eating multiple times a day! Also, contrary to self-driving automation, there are no significant safety risks in automating kitchen environments, meaning that we are likely going to see level 5 kitchens well before level 5 cars! Keep an eye or contribute to this space, it’s full of potential and interesting challenges!

If you want to refer to the original self driving levels and the analogous table from which I took inspiration, have a look here.

Leave a comment